ROTOVER i4-220

Small Parts, Big Difference

Management 4.0: i4smallparts

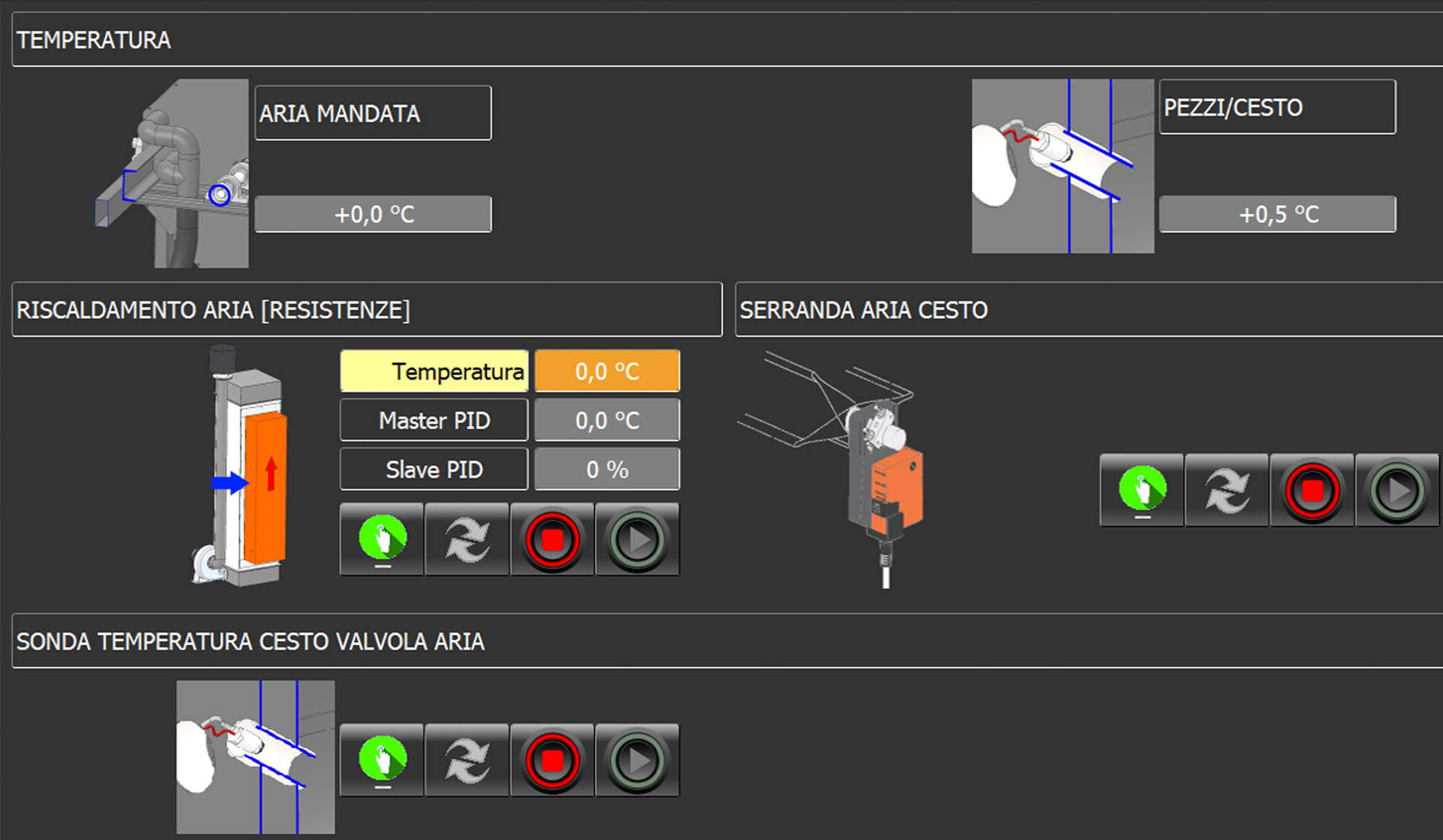

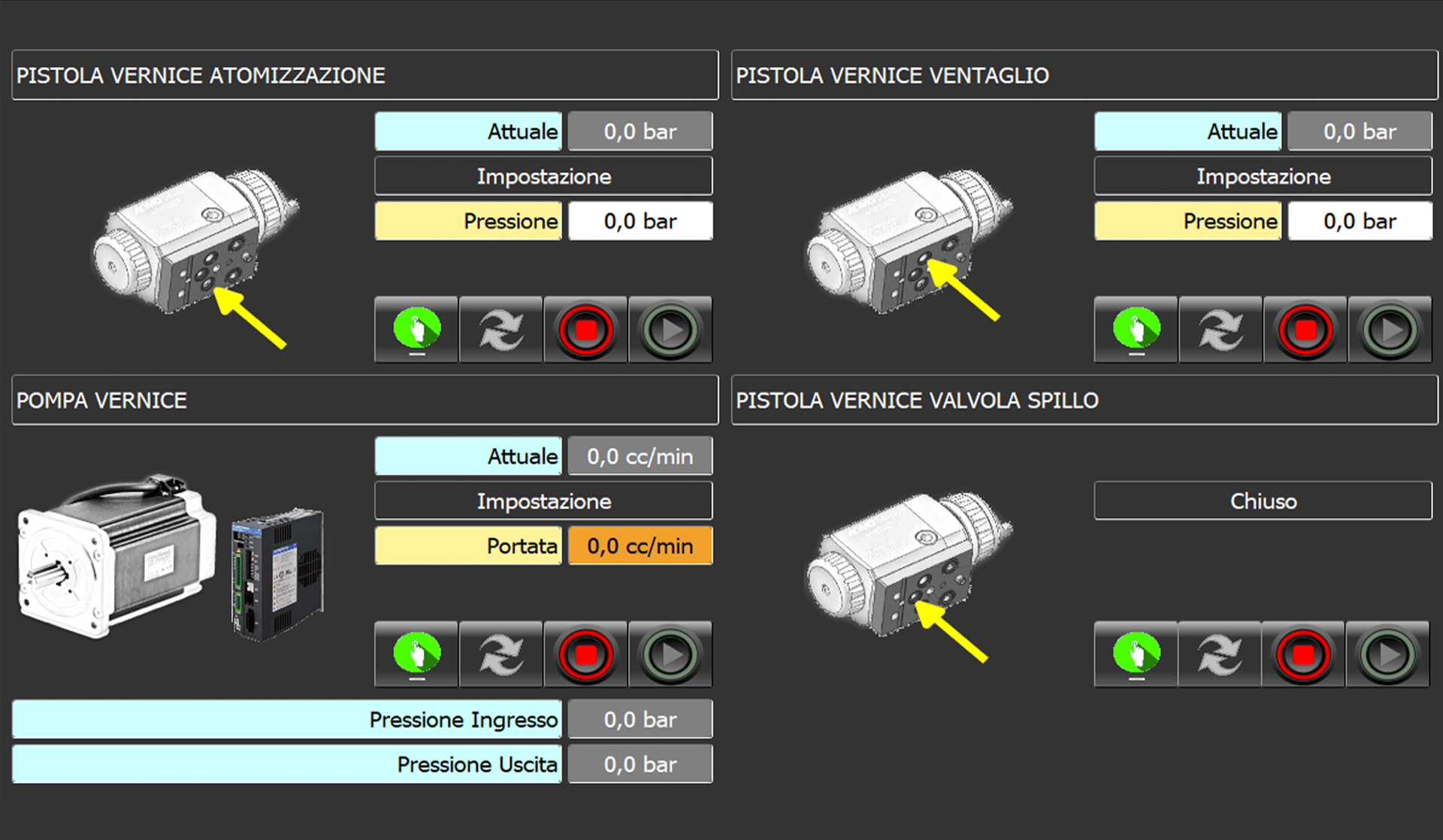

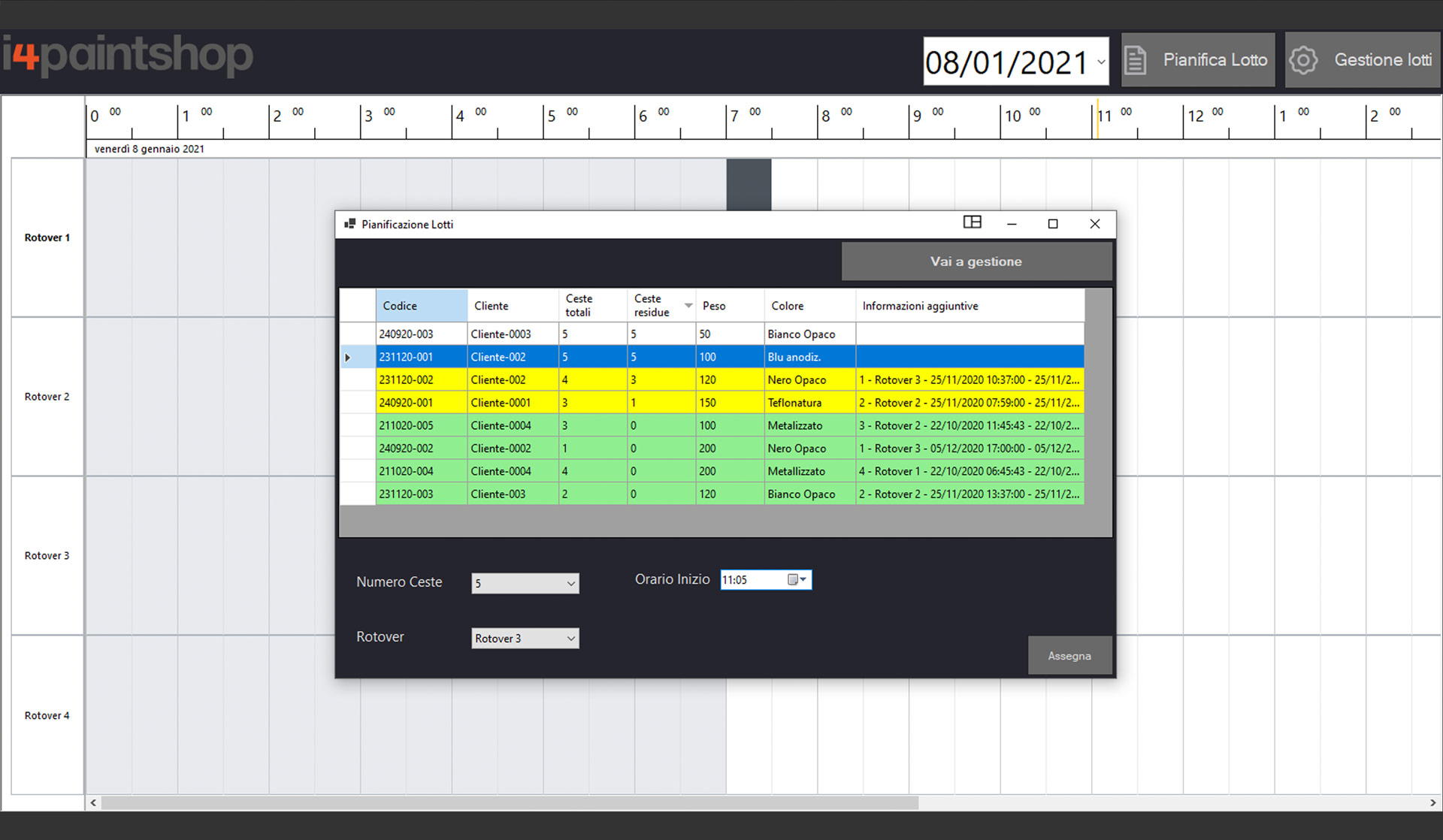

The new machine control software is integrated with Imel which is the module, easy and immediate, that allows you to plan the production on your Rotover (one or more), to automatically load the recipes to be used on individual machines, and to record any changes made during the cycle, giving the possibility to overwrite the old recipe with the new one, which, if required, will be updated automatically on all other machines.

The production is controlled in real time, alerting you of possible delays, thus giving you the opportunity to reschedule the most urgent batches to be shipped, respecting the schedule and always optimizing working time.

Compliance with Act 178 of 30/12/2020 on Transition 4.0 (Italy)

In addition to the advantage of remotely and interactively controlling and managing the work center, the combination of the Rotover i4-220 and the i4smallparts system complies with the requirements of Law 178 of 30/12/20 for obtaining the tax credit equal to 50% of the value of the investment offset in 3 years from the date of installation and interconnection.

The Service

Imel’s specialized service will allow you to evaluate the quality of your product of which you will send us a test batch before any purchase. After the purchase, you will be sent the coating cycle recipe. For each new batch, Imel is willing to send you the coating cycle. The machine is customizable: Depending on the products to be coated, it is possible to choose from a range of different basket shapes and sizes in order to optimize the final quality of the coating. The machine is remotely connected to Imel’s Service Department, which can interact with the operator at any time in the event of faults or requests for assistance, since both the control software and the planning and control module have been developed by Imel’s Research and Development Department.

Why Rotover i4-220?

- Easy control and planning software

- Interchangeable baskets of any shape and size

- High accuracy of process parameters, low power consumption and efficient cycles

- Industry-standard finish

- High productivity

- Operator safety thanks to the closed vacuum chamber

- Prompt and efficient support service

Our Contacts

For information

Fill out the form in its entirety. We will reply as soon as possible. Thank you.