Small Parts Coating

The surface treatment service for small parts

Your Products

The processes that we are able to design embrace various families of finished products such as:

-

high fashion (buckles, buttons, clips, zippers, accessories for footwear …)

-

industrial small parts (seals, springs, rivets, screws …)

-

costume jewellery

-

furniture accessories

-

toys

-

cosmetics (caps, capsules …)

-

and various families of materials: metals, wood, plastic

The process will be defined by the Imel team from the preparation of the pieces (brushing, flaming…) to the finishing (mechanical tumbling, grinding, polishing etc) and the leakage tests.

We are able to define the processes according to the base material and the desired technical and aesthetic characteristics.

The technical characteristics refer to the resistance required according to the environment in which the finished product will be used, i.e.: resistance to corrosion, chemical agents, UV rays, water/washing …

And finally, the aesthetic characteristics that, especially in the fashion markets, become the fundamental requirement and often the most difficult to guarantee: various shades of metal, pearl colors, metallic effects, soft touch rubberized, color combinations, vintage effects, galvanic fixing to ensure durability.

In conclusion, if you are worried about buying a coating machine and not being able to set it up for the product you want, Imel has the solution for you.

Machines

To complete the definition of the ideal process for your use, Imel is able to provide you with the machine suitable for your needs:

- Rotover is the machine that Imel started to sell in the 70s and that still represents a reference point for versatility, ease of use and price.

-

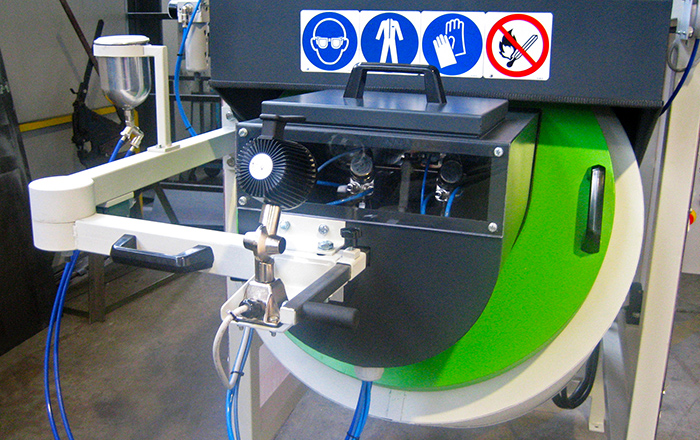

Rotover 130 R2 is the evolution of the machine that was conceived by Imel in the ’70s and that is now proposed with a new software and a design that meets the requirements of ergonomics and safety according to current standards.

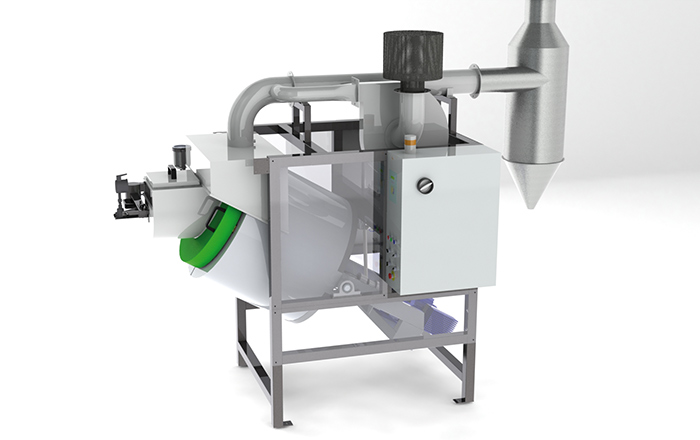

- Rotover i4 220 is the new born of Imel, on the market since June 2021.

For bulkier products, for which the use of Rotover would not be economical, Imel is able to design ad hoc plants on chain (chain on edge painting line).

The After-sales Service

Boasting thirty years of experience in the field, the Imel team is able to provide the following services:

-

installation and start-up of the machine

-

development of cycles (preparation and painting) for new products

-

sending of the cycle to the PLC of the machine control through remote connection

-

technical assistance in real time thanks to the VPN connection of the machine PLC to the control center in Imel

-

mechanical, electrical and software technical assistance with Imel’s direct personnel

Our Contacts

For information

Fill out the form in its entirety. We will reply as soon as possible. Thank you.