SmartMaintenance

The painting line service platform by imel

Would you like to schedule maintenance operations of your painting line and calculate the specific costs quickly and easily?

Meet SmartMaintenance, the new painting line service platform by imel

imel is happy to present the new software package dedicated to the management of paint line service operations.

The lean connection with the PLC that manages the painting line now allows the installation of this package also at plants outside of Imel supply.

i4maintenance

Line upkeep module

i4maintenance

is the module responsible for managing the maintenance activities needed for the optimal of your painting line.

This module allows to:

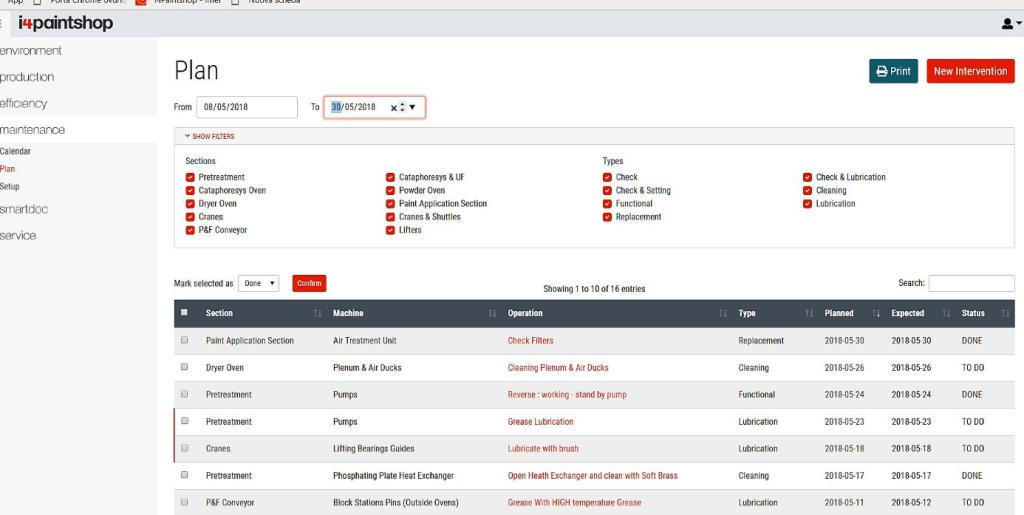

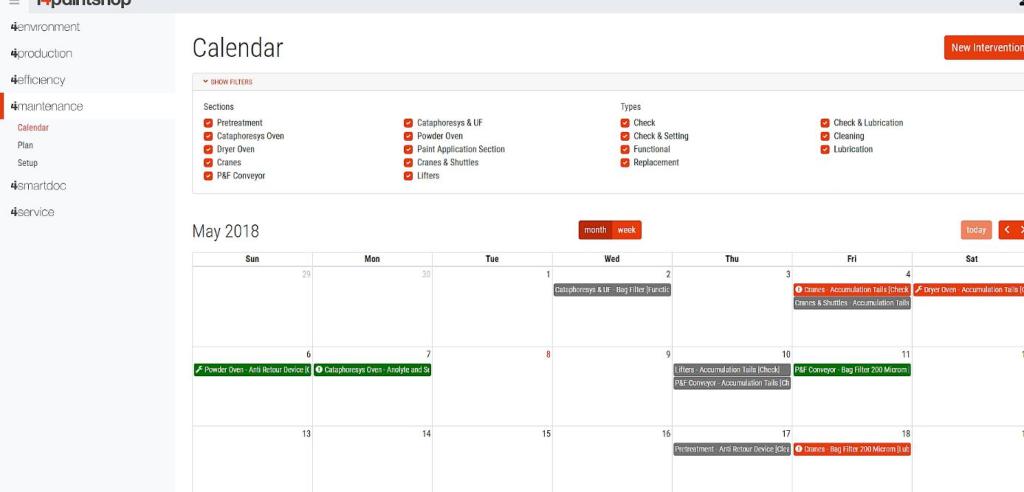

• Plan your weekly/monthly maintenance activities by use of a practical drag and drop calendar

• Customize the maintenance database (included in the offer) by modifying or adding periodic/on-condition maintenance operationsPLC connection makes it easy to implement a preventive maintenance protocol in your painting line

• PLC connection makes it easy to implement a preventive maintenance protocol in your painting line

• Store your maintenance history along with costs incurred, which can then be consulted divided by machine, area or plant

The database containing all the necessary maintenance interventions is included in this offer. After the database is loaded, the usage data parameters are collected from the PLC and compared with the expected lifespan of each component. The calendar is automatically populated when the need for an intervention arises.

The database is then automatically updated every time the maintenance technician intervenes, making the maintenance plan able to adapt to the specific activities and production schedule of the line.

The maintenance calendar is easily readable and modifiable, in fact, it is sufficient to drag the activities on the screen. These are highlighted on the calendar with a colour identifying their status. Each calendar operation is “clickable”, in order to mark it as done and register completion data (e.g. time required, name of the operator, materials and costs) or to consult the operation details / history.

The system makes it easy to create and print a pdf document containing the selected maintenance operations (which can be filtered by time constraint or class of activity e.g. cleaning, substitution, repair…). The operator can then fill in the document while carrying out interventions and load back the information on the system after having performed them, in order to keep track of the activities’ progress.

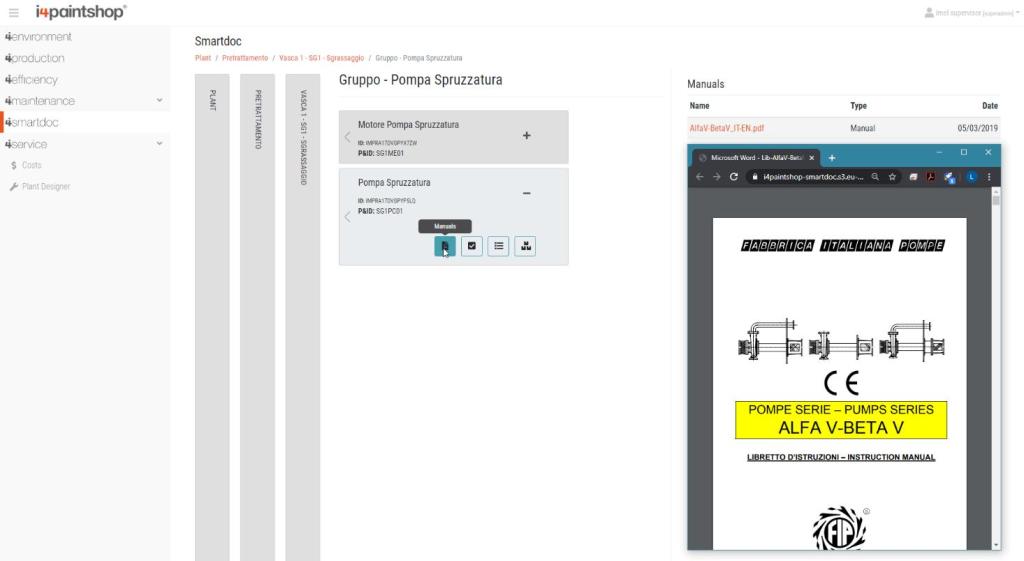

The i4maintenance module is directly linked to i4smartdoc: every maintenance operation is linked to a specific component / area, and it is possible to access its digital documentation by clicking on the link you can find on the related operation details page.

i4smartdoc

digital documentation module

i4smartdoc is the digital documentation storage module of i4paintshop. AII the painting line documents (user manuals, certifications, maintenance activities, spare parts lists, wiring diagrams etc.) are stored in a tree-structured digital archive for easy retrieval and consultation. The i4smartdoc database can be enriched by including machines that are not part of Imel supply.

In addition, i4smartdoc comes with an app developed for smartphones and tablets which allows the operator to access data of the painting line by reading the QR-codes attached to the components.

The i4smartdoc module is directly linked to i4maintenance: from each component window it is possible to access a page displaying all the maintenance operations related to it, both archived and upcoming.

For more information: i4[email protected]