History

Imel began working on the surface treatment of small metal parts in 1980, as market demand grew for a machine dedicated to painting small zips for the fashion industry.

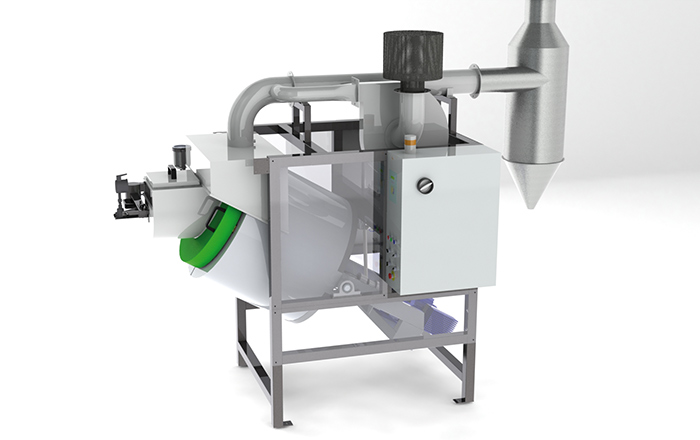

Demand continued to grow and expanded to other sectors: from costume jewellery to high fashion, to various fasteners used in manufacturing and construction. Imel decided to devote itself to the development of this new machine, naming it ‘Rotover’.

Over the years, several models of the same machine have followed one another, without ever losing sight of the key principles of the Rotover philosophy: robustness, versatility and ease of use and maintenance.

The processing of small parts is a sector in which Imel constantly invests in terms of research and development: the goal is customer satisfaction, which requires increasingly specific processes and ever higher standards. Imel boasts over 40 years of experience in the sector, with almost 500 Rotover product customers worldwide.