The BIG DIFFERENCE

for small parts

New features in mass painting

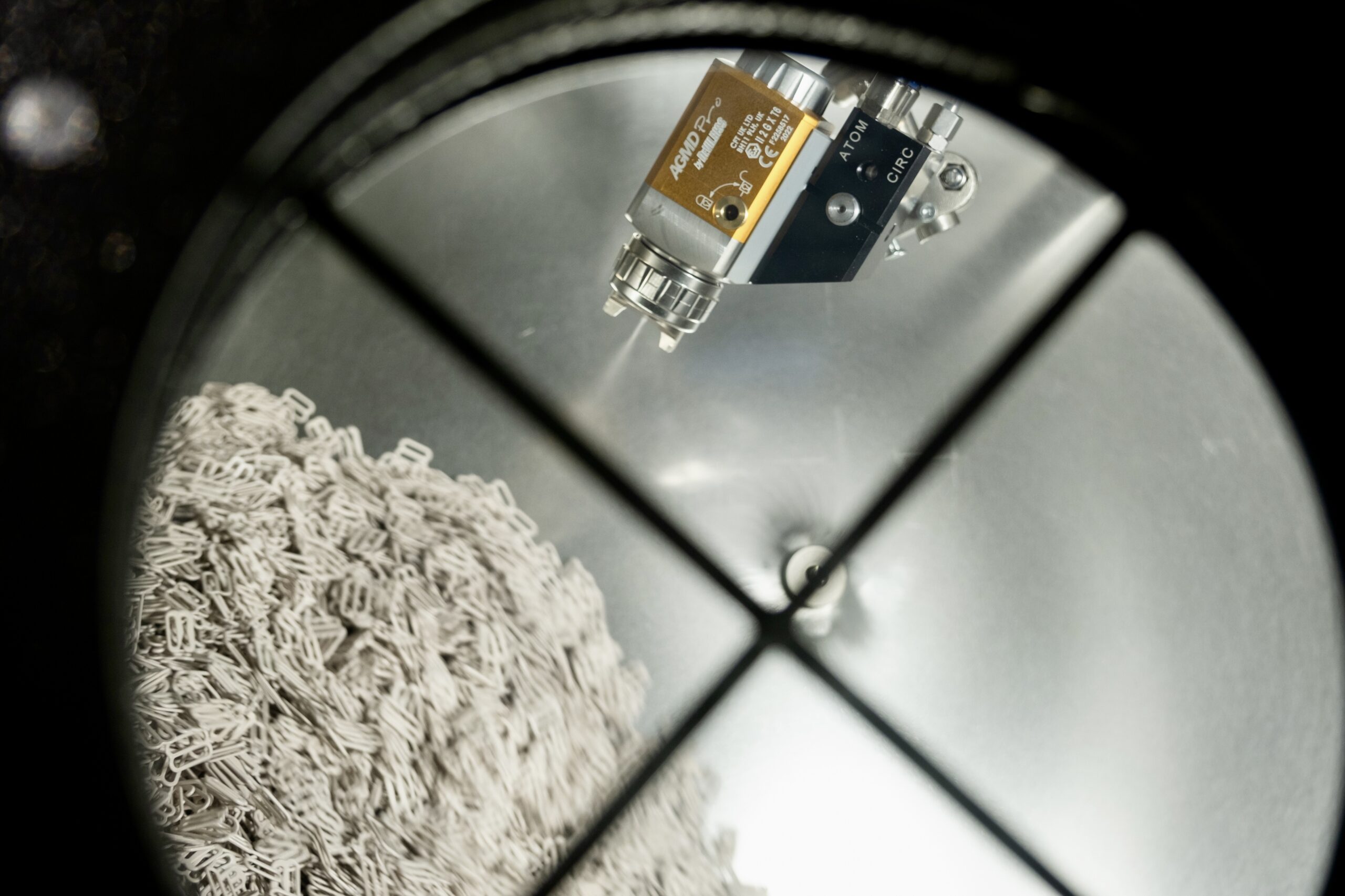

Uniform, high-quality finishes

Each piece receives uniform, precise and repeatable treatment, even on complex geometries.

Removable, customisable basket

One of the strengths of the new Rotover is the versatility of its baskets. The basket sections are completely removable and available in a variety of configurations to adapt to every operational requirement.

- Basket dedicated to paint testing for optimal results right from the early stages

- Highly customisable baskets to suit the user’s specific requirements

- Optimisation of the production process thanks to the flexibility of the baskets

The new spraying system consists of a high-precision volumetric pump and an automatic spray gun, designed to ensure uniform and controlled application of the product. The parameters relating to the entire spraying cycle, as well as those specific to each phase, are automatically retrieved from the database of preset cycles.

However, the operator can intervene at any time, easily setting or modifying these parameters even during the cycle, depending on production requirements or the characteristics of the workpiece.

The dual-circuit air heating system allows for precise and fully automatic temperature management, ensuring maximum control at every stage of the process.

The temperature can be customised for each stage of the process, ensuring optimal conditions for consistent, high-quality results that meet the highest production standards.

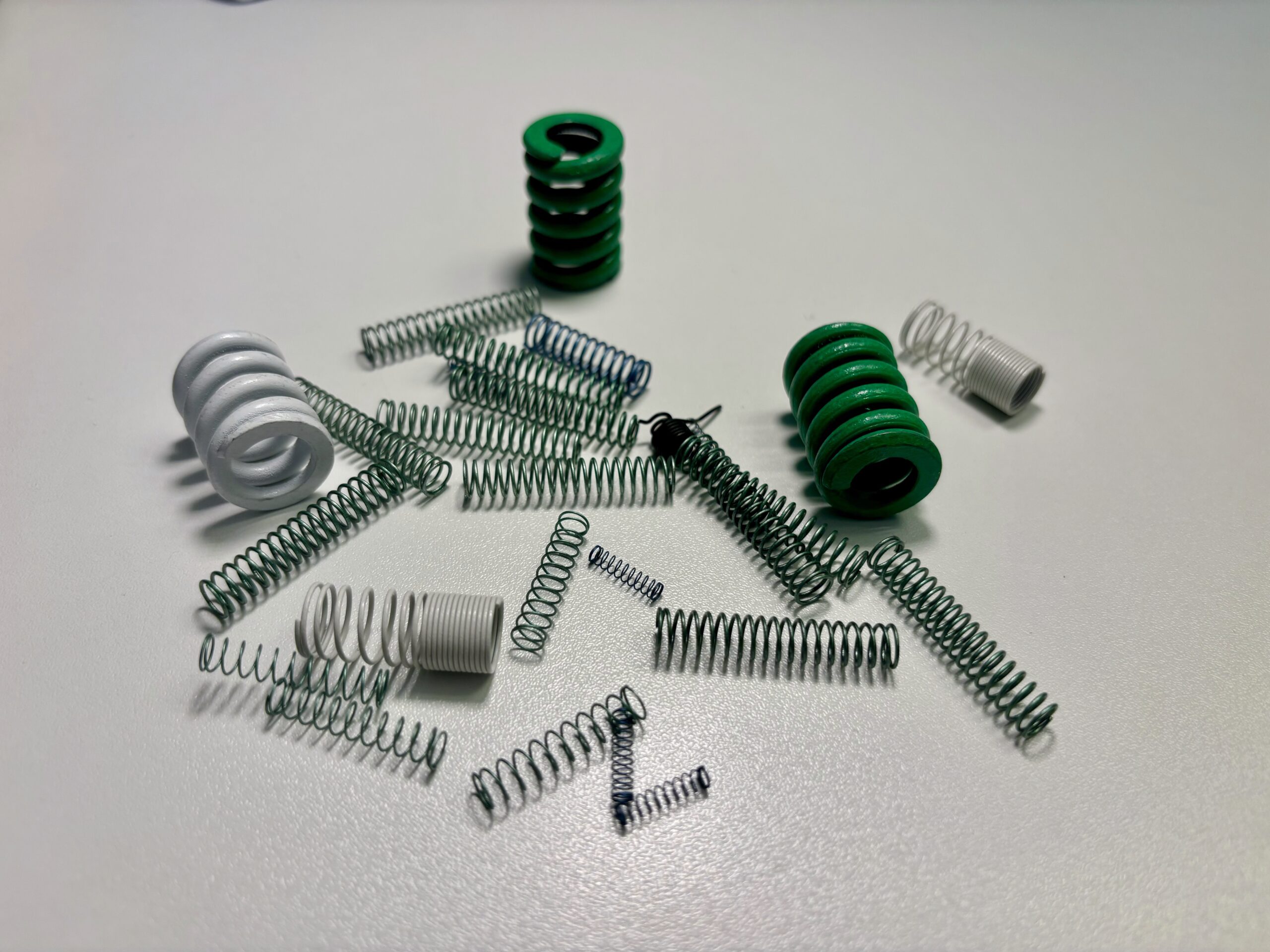

Painting and protective treatments

The perfect combination of aesthetics, quality and durability.

Painting is not just a matter of aesthetics: it adds real value to every product. On the one hand, it enhances the visual appearance, adding colour, shine and high-quality finishes; on the other, it plays a fundamental role in terms of functionality and protection.

Treatments include painting, waxing, Teflon coating, adhesive application, anti-corrosion and protective treatments, all designed to ensure resistance, durability, and high performance over time. A strategic investment for those who focus on quality and reliability in the final result.

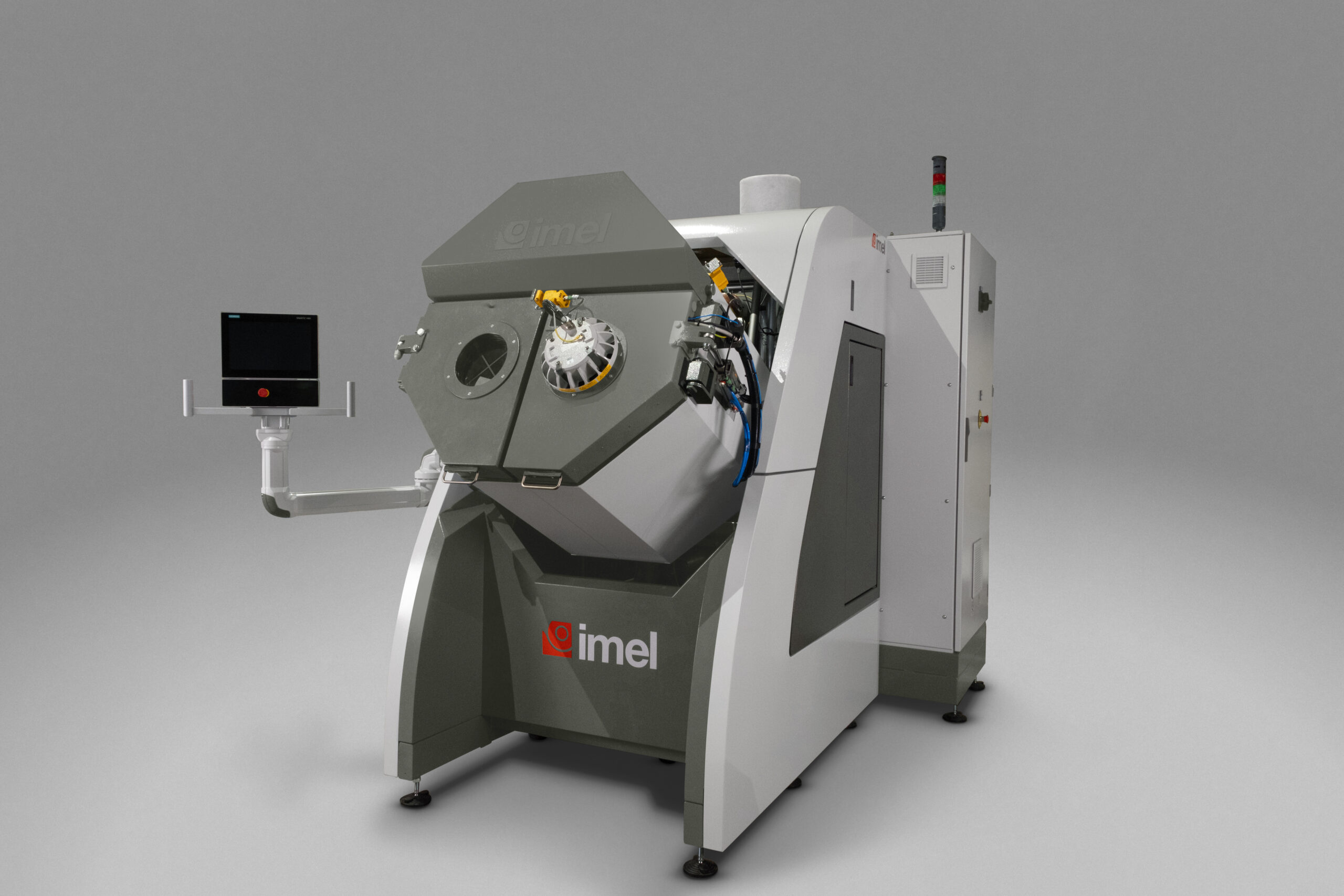

The operating system

Interactive remote control and management of the work centre

It allows multiple rotover machines to interact with each other, creating an automated production line that is monitored at every stage.

- Integration with the customer’s MES

- Optimisation of working times

- Automatic recipe loading

- Product recipe management

- Production and process data collection

- Real-time production control

Safety for

the operators

The new Rotover has been designed in compliance with the most stringent regulations regarding health protection, worker safety and environmental protection. Thanks to its innovative sealed chamber, which operates under negative pressure, it guarantees:

- Absence of vapours and solvents in the workplace, helping to create a safer and healthier working environment for employees.

- Secure access at every stage of the process, thanks to an automatic, controlled door opening system that maintains high standards of protection without compromising productivity.

Services included

To ensure complete and personalized support

Rotover is supported by a range of services:

- Customised tests: painting tests on customer products.

- Training and commissioning: training and support for optimal installation.

- Rapid assistance: interventions also remotely.

- Technical support: creation of paint recipes for perfect results.

NEW ROTOVER i4

TECHNICAL DATA:

- Maximum pieces volume loadable 45 l (versione 220) / 70 l (versione XL)

- Filtration class EN ISO 16890

- Drum tilting range -15° … +35°

- Average electric consumption -8 kWh

- Voltage 400 V, 50 Hz

- Pressured air pression needed 6 bars

- Weight 1600kg

- Size 2600x2000x2100(H) mm

ESG

Rotover GREEN

Rotover is the ideal solution for coating small parts, combining innovation, efficiency and sustainability. Designed to comply with ESG principles, it offers a responsible and cutting-edge approach.

WATER-BASED PAINTS

It can use water-based paints and minimize waste, ensuring a reduced environmental impact.

SAFETY

Improves safety and working conditions thanks to its ergonomic design and low harmful emissions.

REGULATIONS

It promotes transparent production processes that comply with international regulations.